Professor recycles coffee as 3D printing material

The University of Colorado Assistant Professor Micheal Rivera found a way to use coffee grounds for 3D printing. Mixing the caffeinated by-product with a few ingredients enabled him to create sturdy, biodegradable projects once they harden. Rivera hopes it inspires others to discover other sustainable 3D printing techniques.

More people want to create a sustainable, environmentally friendly future, but we need new ideas to make that possible. We must find new ways to recycle or repurpose waste products, and this coffee 3D printing method is one of the most interesting ones right now. Aside from being a nifty recycling technique, it has numerous applications.

This article will discuss how Micheal Rivera developed this unique 3D printing method. Later, I will elaborate on 3D printing to help readers understand this discovery further.

How does the coffee 3D printing technology work?

Feeding raw coffee grounds into your 3D printing machine will break it. That is why Micheal Rivera and his team had to turn it into something akin to thermoplastic beforehand.

The University of Colorado said they mixed it with cellulose and xanthan gum. They are common food additives that degrade in compost bins easily.

Then, the researchers blended them with water, so “you’re pretty much shooting for the consistency of peanut butter.” Still, they couldn’t load that goo into their 3D printer.

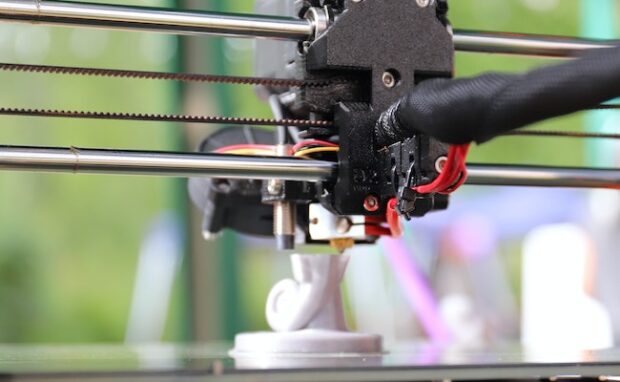

That is why Rivera modified his printer with plastic tubes and a coffee-paste syringe. Next, they tested their new coffee 3D printing method. Surprisingly, their creations were as tough as unreinforced concrete!

“We’ve made objects with a ton of usage,” Rivera remarked. “We’ve dropped them, and they haven’t broken yet.” Science update website New Atlas said he and his created multiple objects with their new technology, like pieces of jewelry and disposable espresso cups.

Furthermore, adding activated charcoal applied electrical conductivity to the materials. The University of Colorado researchers also discovered coffee 3D printing is great for plant pots.

You usually cultivate indoor plants by growing them in a pot first, then taking them out and into your plot. Conversely, you could directly plant a seedling with its coffee-printed pot in the ground.

You may also like: Coffee consumption based on genes

The unique 3D-printed container will decompose, providing nutrients for the developing plant. Biodegradability also turns coffee 3D printing material into a more sustainable alternative to conventional plastics.

Unlike their creation, thermoplastics only decompose after a thousand years. Despite their success, Rivera acknowledges that his coffee 3D printing method is unlikely to become widespread.

Instead, he believes it could guide the development of other sustainable 3D printing materials. Perhaps those projects could replace plastics in the future.

How does 3D printing work?

Some readers may not be familiar with 3D printing. It typically layers molten plastic to produce various shapes. It has several applications, from creating keychains to producing prosthetic implants.

The dental industry also uses this technology to produce dental impressions that accurately match a patient’s mouth and teeth. In May 2023, Mark Skylar-Scott, assistant professor of bioengineering at the Stanford School of Engineering and Medicine, created living organs with 3D printing.

You may also like: Scientists turn flies into biodegradable plastic

Skylar-Scott starts by preparing stem cells, which the body uses to create specialized cells. Then, he and his team applied a special formula to turn them into organ cells for 3D printing tissue.

“Each line of stem cells we are developing are genetically engineered to respond to a specific drug,” the professor explained. “Once they sense that drug, they differentiate into specific cell types.”

At the time of writing, the Stanford scientists had only made a tube-like structure like a human artery that pumps fluid. They hope to produce other body parts with further research and development.

Conclusion

A University of Colorado professor developed 3D printing material made from coffee grounds. As a result, he found a sustainable alternative to thermoplastics used by most 3D printers.

The material was biodegradable, making it suitable for indoor gardening. Moreover, it is highly durable and can mix with activated charcoal to gain electrical conductivity.

Gain additional information about the coffee 3D-printing method from the Association of Computing Machinery website. Also, learn more digital tips and trends at Inquirer Tech.