Why perovskite is solar energy’s next evolution

The world is more committed to sustainability nowadays. Consequently, experts worldwide have been developing ways to improve renewable energy, and perovskite is one of the most promising methods.

The US Department of Energy says perovskite is a “family of materials” that can help produce more effective and efficient solar cells.

READ: Japanese solar cells to match 20 nuclear reactors’ total energy

Numerous countries have been cultivating this potential. For example, Japan aims to use perovskite cells to bolster its national energy plan.

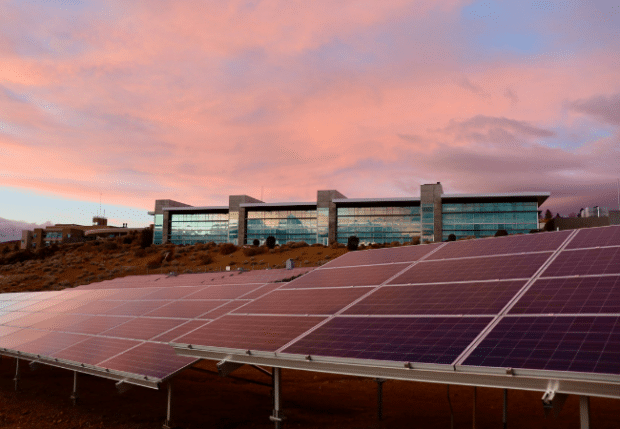

Philippine President Ferdinand “Bongbong” R. Marcos Jr. led the groundbreaking for the country’s largest solar farm.

Soon, it may enhance this facility further with perovskite due to its unique potential.

What is perovskite?

Imagine solar energy technology that can you literally paint on the side of a building! That's the promise of perovskite solar cells, groundbreaking new material with big potential for America's energy future. ☀⚡Learn more ➟ https://t.co/yTNjFKDPxZ #NewEnergyRealism pic.twitter.com/xNOsZMzsuL

— U.S. Department of Energy (@ENERGY) March 12, 2018

MIT News explains the term “perovskite” originated from Russian mineralogist Lev Alekseevich von Perovski.

In 1839, he discovered the original mineral perovskite, which is calcium titanium oxide (CaTiO3). A material belongs to the family of perovskites if it can form a structure similar to CaTiO3.

READ: Brain implants could one day help disabled persons speak again

Interesting Engineering says perovskite materials include methylammonium lead halide and cesium lead halide.

These compounds have exceptional compositional flexibility, making them suitable for high-tech applications like memory chips and ultrasound machines.

How do you make perovskite solar cells?

The US Department of Energy provides the following general overview of perovskite solar cell (PSC) production. Note that these steps may vary in real life, depending on their applications:

- Material creation: Manufacturers mix precursor salts to form a perovskite ink solution. If they deposit the material as a vapor, they will only mix the salts once they’re on a cell.

- Cell production: They deposit an ultra-thin layer of perovskite ink or powder. Next, they heat the cell to set the film. Also, the manufacturer may add layers on top or below that layer to direct the flow of electrons.

- Module completion: If the manufacturer is creating a module, it will scribe channels into them via laser. Next, they scribe electrical contact channels to wire the cells together. Afterward, they add edge sealant and encapsulant for weatherproofing.

- Testing and development: Lastly, the manufacturer gauges the PSC’s durability and efficiency.

What are perovskite’s advantages?

Nowadays, more countries like Japan are testing the use of solar panels instead of silicon due to these advantages:

- PSCs can convert 30% of sunlight into electricity. Conversely, traditional silicon panels can only generate roughly 25%.

- People can manufacture them at room temperature via simple printing and coating techniques. As a result, they can reduce production costs.

- They’re thin and lightweight, letting them integrate into portable devices and building materials.

- Innovations like perovskite-silicon designs boost energy output while reducing material use. Consequently, it can help countries achieve their global sustainability goals.

- More importantly, these revolutionary solar cells maintain higher efficiency in high temperatures. That is why they’re likely suitable for tropical nations like the Philippines.

What are perovskite’s disadvantages?

Despite being a revolutionary technology, perovskite solar cells still have flaws:

- The cells are sensitive to UV light, oxygen, moisture, and other environmental factors. Consequently, users must encapsulate them properly to prevent rapid degradation.

- The production uses lead, which raises health and environmental safety issues.

- Transitioning from small-scale lab production to large-scale manufacturing makes it difficult to maintain quality and efficiency.

- High temperatures may compromise their structural integrity.

- Perovskite cells typically have a lifespan of only 2.5 years.

READ: Apple slashes Vision Pro headset production due to design issues

Fortunately, ongoing research and development could overcome these challenges.

For example, the University of Surrey’s Advanced Technology Institute (ATI) extended the operational lifetime of these cells by 66%.